“Look before you leap”

“Look before you leap”

We are all taught about this in our childhood.

And,

Our parents were always there to look at us before we took a leap.

In your workplace,

You are the parent and your workers are your children.

You can’t take any risk with them.

You have to ensure a safe workplace for them.

Thus,

In this article I am going to take you along the workplace safety awareness tips.

In fact,

I am going to tell you the exact things you need to keep in mind to ensure safety in your workplace:

- Provide a clean environment to your employees

- Keep the First Aid Kit always stocked up

- Proper handling of combustible materials

- Train your employees in proper handling of equipments

- Provide work-specific uniform and protective gears

- Mark the danger zones clearly

- Plan for emergency exits

- Emergency procedures should be implemented

- Provide ergonomic furniture

- The employees should be made aware of the workplace risks

- Ensure regular servicing of tools and machinery

- Provide a stress free environment to your employees

- Ensure proper ventilation

- Provide health insurances to your employees for medical emergencies

- Don’t over strain your employees

- Have regular meetings on workplace safety measures

- Ensure fire safety measures

- Reduce physical labor

Let’s Delve Deep:

1. Provide a Clean Environment to Your Employees

Did you know?

Did you know?

Why ancient people used to survive longer?

It’s just because of the clean and serene environment around them millions of years ago.

I know, I know,

It’s now impossible to generate the same environment.

But hold on,

You can do a bit for your workers

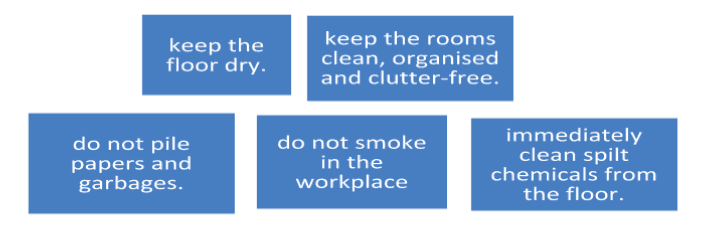

Ensure the following rules in your workplace:

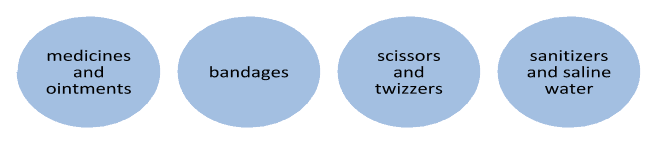

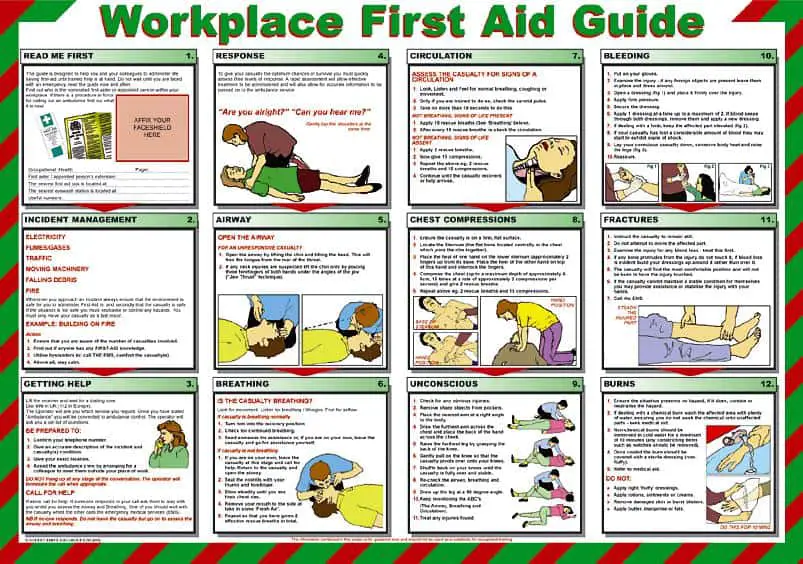

2. Keep the First Aid Kit Always Stocked Up

A first aid kit is all known to us.

A first aid kit is all known to us.

But wait,

Do you know the exact things to be kept in it?

Let’s have a look:

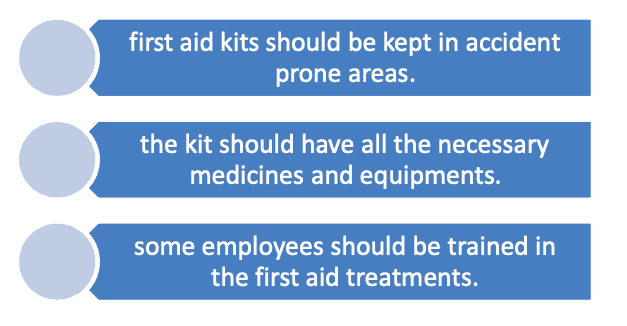

And what about its proper utilization?

Ensure that:

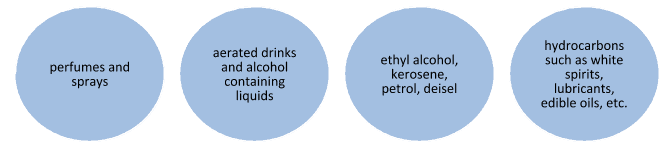

3. Proper Handling of Combustible Materials

Combustible materials fall under two understated categories:

A. Careful handling of flammable liquids:

Here are some to be taken into consideration:

After a lot of Google search,

I have come up with the following tips to handle flammable liquids:

Do not keep more than a day’s supply of these liquids in the workplace.

Do not keep more than a day’s supply of these liquids in the workplace.- Store them in fireproof containers in a well ventilated room, open space, or in a suitably constructed store room.

- Decanting of flammable substances should be done in a well ventilated area to clear up any spillage.

- No potential ignition sources should be there in areas where flammable liquids are stored.

- Intermediate Bulk Containers are nowadays replaced with steel cans to store flammable substances. These pose risk in case of fire breakouts. In fact, researches show that in UK serious fire rates have increased due to the usage of IBC in workplaces.

- Do not keep flammable substances near combustion zone, fire exits, gas cylinders and electrical sources.

- Train the workers to handle safely all the flammable liquids and to dispose them off safely in an open area, away from the workplace.

B. Precautions with flammable materials:

Firstly, let’s know the flammable materials:

Now when you are well aware of the combustible materials let’s focus on the safety measures to be taken into consideration:

- Minimize the use of these materials with their alternatives and keep them away from the escape routes.

- Keep them in stock in separate building, other than that of your main workplace building.

- Train your employees on safe storage and handling of these materials.

- Keep these materials inside a fire proof cupboard, made of iron or steel.

- In case of handling the gas cylinders and gas pipes, learn the precautionary measures while handling these items with the gas suppliers and train the employees to deal with it in case of combustion.

Keep fire extinguishers in front of gas cylinders and gas pipes.

4. Train Your Employees in Proper Handling of Equipments

As you teach your child in safe handling of gadgets.

As you teach your child in safe handling of gadgets.

It becomes inevitable to teach your employees too in proper handling of equipments.

Else,

Their life might be in danger or you might run at regular loses.

Therefore,

-

- Ensure the use of heat equipments which have a thermostat to regulate heat.

- Have them serviced regularly.

- Switch them off when not in use.

- Do not use them on combustible and explosive substances.

- Avoid ventilation points on machinery becoming clogged.

5. Provide Work-Specific Uniform and Protective Gears

Work-specific uniform might be divided into the following 3 categories:

A. MEDICAL UNIFORM:

Being contaminated with bacteria and viruses is the major concern of the medical field. Therefore, masks, gloves and aprons are a must. The uniform need to be breathable and have to be made of double ply panels which provide protection against punctures.

B. WORKWEAR FOR INDUSTRIES:

Industrial workers get exposed to fire, UV rays, and heat. Thus, sturdy garments which provide protection from the above mentioned factors should be used. In particular they have to be fire retardant and smolder proof.

C. WORKWEAR FOR FOOD PROCESSING FACTORIES:

Their uniform need to be made of comfortable and breathable fabrics with anti-bacterial protection.

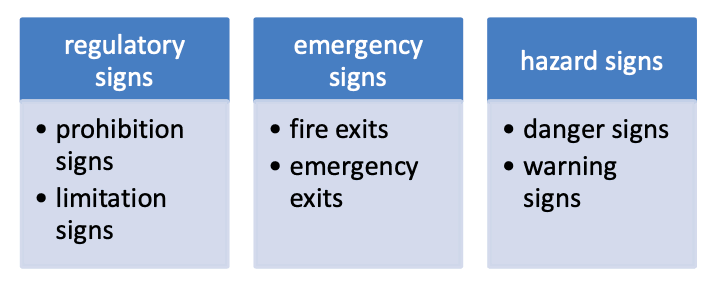

6. Mark the Danger Zones Clearly

Did you think of some ghost or zombies?

Did you think of some ghost or zombies?

No, I am not out of my senses.

What I mean by danger zones are:

-

- Fire places

- Combustible materials

- Flammable liquids

- Hot works

- Electrical wirings

And,

All these crave to be marked as dangers for their careful handling and proper measures while around them.

Thus, it becomes necessary to mark them or they might put your life in danger.

Some common categories of signs that need to be marked for the safety of your workplace are:

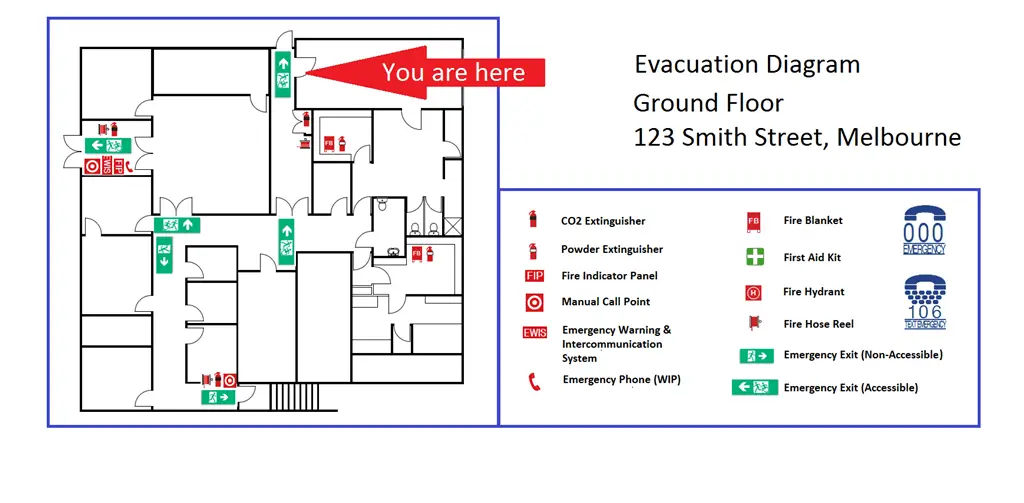

7. Plan for Emergency Exits

Have you heard the phrase: “A Narrow Escape”?

Well,

Emergency exits provide you with the same.

They are your narrow escape routes in times of danger.

Just keep in mind the following:

- Every room must be connected to the emergency exit.

- The emergency exit should never be blocked.

- It should not contain sturdy doors and windows.

- Proper maintenance of the emergency doors and windows should be done. It should be kept rust free.

- Mark emergency exit signs on the floor as well.

8. Emergency Procedures Should be Implemented

Now this becomes compulsory to run your business and to make it soar high in the market.

Don’t worry,

I have found some great tricks for you:

- Keep a check on natural disasters through the media and warn your employees of the impending danger.

- Ensure that all your employees have insurance policies.

- Regularly check your competitors and try to implement better policies in your business.

- Have a well maintained emergency management program.

- Make sure that all your employees undergo emergency response and evacuation training courses.

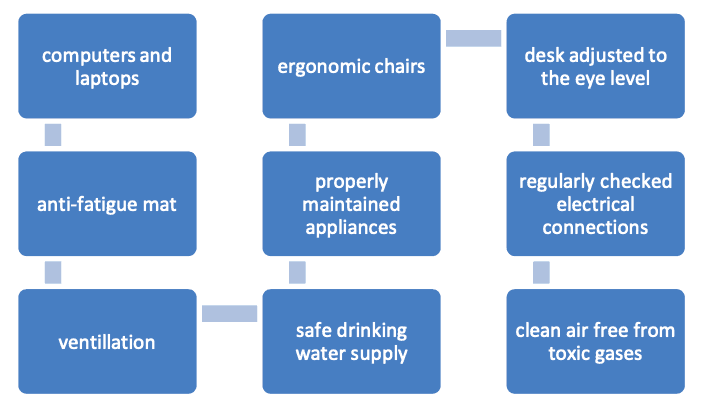

9. Provide Ergonomic Furniture

Ergonomic!

Ergonomic!

In simple words it means things which provide comfort.

Now you know it better that work isn’t possible in discomfort.

You need to have tools and equipments and furniture around you which aids your physical comfort.

So do the workers.

When provided with the right components,

The workers tend to produce more.

Just provide them with the following:

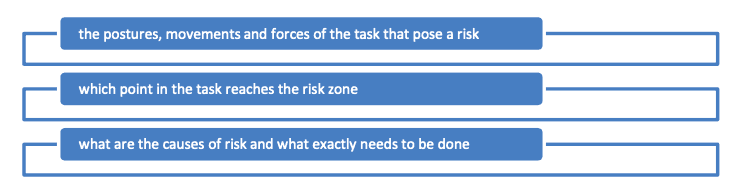

10. The Employees Should be Made Aware of the Workplace Risks

To avoid any fatal accidents,

Intimidate your workers about:

11. Ensure Regular Servicing of Tools and Machinery

Proper maintained tools and machinery pose less threat while work.

Proper maintained tools and machinery pose less threat while work.

Therefore,

It becomes necessary to:

- Regularly check for wear and tear in machine parts

- Quick fixes

- Repair of damaged parts

- Regular checking by experts

- Replacement of weak parts

12. Provide a Stress Free Environment to Your Employees

STRESS!

Under pressure, employees generally tend to stress out.

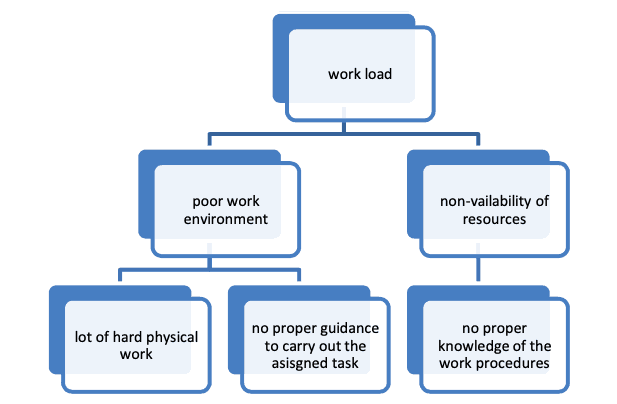

Stress may be fatal and can be caused due to various factors such as:

Need ways to deal with it?

I will help you out:

- Give them breaks at regular intervals

- Ensure the work environment is healthy

- Provide proper ventilated rooms with adequate health facilities

- Reduce manual labor and replace it with equipments

- Give them proper training to handle the equipments

- Talk to them if they tell of any concern

- Make them feel safe when at work

13. Ensure Proper Ventilation

Yes,

You thought it right.

Ventilation is required for the exit of toxic gases and odor.

It provides the workers with a clean air to breathe and they do not fall sick easily.

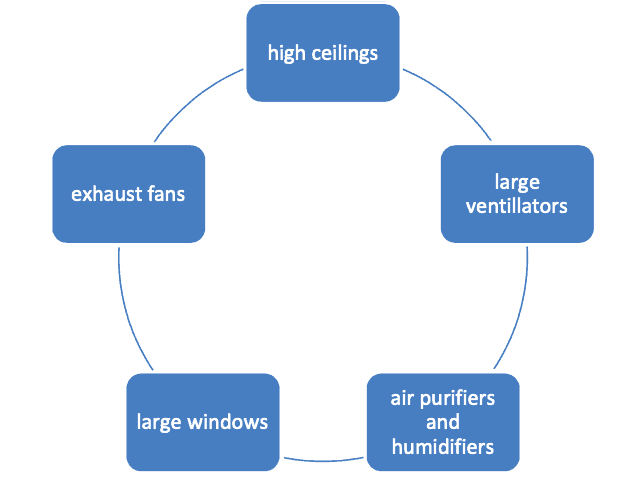

Proper ventilation system includes:

14. Provide Health Insurances to your Employees for Medical Emergencies

Illness and diseases never warn you before they come.

They knock at your door suddenly and leave you helpless.

To avoid this helplessness provide them with certain facilities:

- Medical insurance

- Provident fund

- Regular health check-ups at your workplace by a certified doctor

15. Don’t Over Strain Your Employees

Straining your employees with lot of hard labor might lead to your own loss as:

Straining your employees with lot of hard labor might lead to your own loss as:

- They might quit the job

- They might fall sick and ask for leave regularly

- Mishandling of the equipments

- Go out of their mind while handling important tasks and might end up risking their own lives

Ensure that they carry out only the amount of work they can deal with.

16. Have Regular Meetings on Workplace Safety Measures

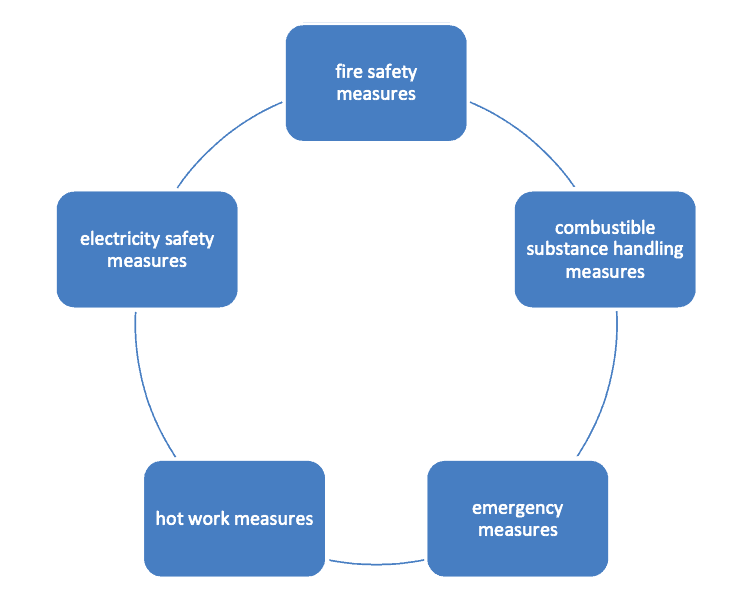

Workplace safety measures include:

- Talk to them on these issues regularly

- Hold meetings by experts in these particular fields

- Hold workshops and training camps

- Ensure that they implement these measures

- Keep a supervisory body to keep a check on the employees

17. Ensure Fire Safety Measures

Fire safety becomes mandatory for any workplace.

Know all about it in details in our article:

{15 Safety Precautions To be Taken to Prevent Fire in Workplace}

18. Reduce Physical Labor

Manual labor is the other name for physical labor.

Manual labor is the other name for physical labor.

It is more evident in construction sites where labourers need to:

- Carry heavy loads

- Dig pits

- Carry construction works with bricks and cement

All you need to do is,

Alternate machines with the workers.

In other words,

Introduce machineries which can reduce the work of manual labors and train them in the working of those machineries.

NOW IT’S YOUR TURN

So I hope this post helped in showing you the safety awareness tips in workplace.

And now I’d like to hear from you:

Which strategies from today’s post have you already followed or are eager to follow?

Or maybe you have a question about what you have read today.

Either way, let me know in the comment section below right now.