According to reports, in 2016, in the U.S nearly 20% of the deaths on the construction sites happened due to not wearing of the safety vests.

According to reports, in 2016, in the U.S nearly 20% of the deaths on the construction sites happened due to not wearing of the safety vests.

According to Janice Comer Bradley, CSP, ISEA’s technical director:

“Low-visibility hazards are an even greater risk where there are complex backgrounds, as found in many occupations such as working on foot in close proximity to construction equipment and vehicle roadway traffic. Vehicle operators cannot recognize a worker who is wearing inadequate or non-enhanced-visibility clothing in sufficient time to avoid an accident.”

In this article I am going to tell you in details about the importance of wearing safety vests in the construction sites, what are the OSHA guidelines, the history of safety vests, safety vests statistics, the right time to wear safety vests and what will happen if you try to avoid safety vests while on work.

So, let’s get started without further delay.

Benefits of Wearing Safety Vests in Construction Sites

Safety vests are high visibility vests and have immense benefits for workers in the construction sites. Some of them are listed below:

1.) Your workers would be visible to you all the time. In other words you can identify them from far whenever required.

2.) In case of traffic areas, wearing high visibility vests would help the drivers to locate you from far and thus avoid fast driving and accident.

3.) The instances or risks of accidents would be reduced to a great extent.

4.) It creates a safe working environment for workers when they wear safety vests as they feel safe in it.

5.) It creates team spirit as the same color code for a particular group help workers to identify themselves and elevates their spirit of work in sites.

The Negatives of not wearing safety vests

⊗ The chances of you being hit by a vehicle would increase as without the vest, you won’t be visible to the truck drivers.

⊗ People might not indentify you with your work field.

⊗ You won’t feel safe while working.

How are Safety Vests Made?

Safety vests are generally made with mesh or some other lightweight fabric mixed with reflective materials and fluorescent colors.

Safety vests Statistics

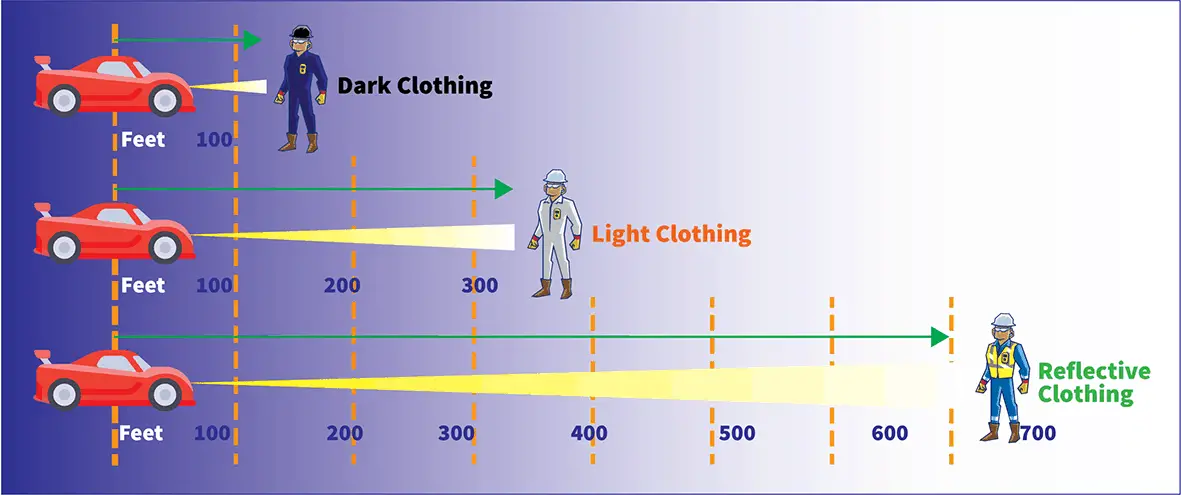

Statistics show that high visibility clothing/safety vests are visible from the furthest distance as compared to normal dyed clothes. When light from vehicles falls on clothing the visibility statistics is given below:

| DARK CLOTHING | LIGHT CLOTHING | SAFETY VESTS | |

| FEET | 100 ft | 300 ft | 700 ft |

The U.S Occupational Safety and Health Administration ( OSHA) has identified four focus hazards and has given the statics from the Construction Research & Training (CPWR) to illustrate the hazards caused due to not using safety vests:

-

-

- From 2011-2015, nearly 804 construction workers have died due to struck-by injuries. This amounts to 48% of the total workers.

-

-

-

- 57% of the struck-by vehicle deaths happened in the work places because of not wearing safety vests.

-

-

-

- 20% deaths occurred in the roadways.

-

-

-

- 96% of the deaths occurred due to struck by an object or equipment.

-

OSHA safety vests Requirements

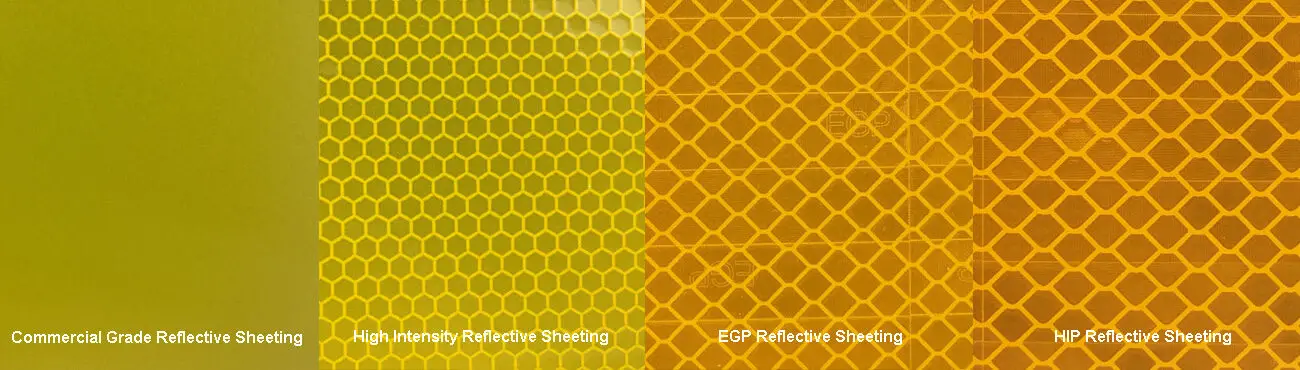

OSHA requires the safety vests to follow ANSI/ISEA 107-2015 standards. The ANSI/ISEA 107-2015 declares that wearing safety vests is mandatory for workers visibility in at night, in low light conditions and in poor weather conditions. It describes safety vests as follows:

-

-

- Clothing design that meets the needs for durability, functionality, comfort and other working hazards.

- Clothing that meets the requirements for the background and the combined working retro-reflective materials.

-

-

-

- Clothing that meets the photometric and physical performance requirements for the retro-reflective materials.

- The proper care, maintenance and labeling for the types and classes for safety vests.

-

Safety vests training/how to wear them right?

Following are the instructions on wearing and handling safety vests:

→ Make sure that the safety vests fit you right. If they are too tight or too loose, you won’t feel comfortable in them and you will be distracted while working. Even loose vests can get caught inside the machines and cause danger instead of protecting you.

→ You have to follow the care label instructions (like how to maintain and how to handle) on the vests very carefully. For example, there would be instructions on how to wash and how many times to wash the vest and not following the instructions can decrease the visibility of the vests in work places thus making it of no use in future.

→ Choose the right vest for your purpose. There are vests designed to serve different purposes. For example, some are designed to be visible in high glares while some are meant to be visible in dim lights.

→ Make sure to replace the safety vests at the right time. Safety vests are likely to get damaged with excessive use and also depend on various factors like exposure to sunlight, daily or occasional use, mishandling them, frequently washing them. When your vests have faded or torn or are inappropriately sized, be sure it’s time to replace them.

History of Safety Vests

Safety vests or high visibility clothing was first created by Bob Switzer while he was hurt unloading crates in California in the 1930s. After that incident he was determined to do something for the safety of the workers in the construction sites. His dream was to develop equipment or something to prevent impending injuries as the one he had to go through.

His brother Joe was then experimenting with fluorescent chemicals since several years. Together they put their experience and innovative thinking together to develop prototypes of reflective materials. After a lot of experimentations, both the brothers were successful in developing a fluorescent paint called “Day Glo”, which had the ability to shine even in the day light.

But it was only after WWII that their innovation was put to impact for public safety in the workplaces.

Before we say Good Bye:

Visibility amounts to safety!

The more you are visible in your work sites, the less prone you are to injuries and fatalities. And to make yourself visible, the only way is to wear a safety vest. Also, not wearing safety vests might end up in some legal issues for your construction sites. So, why take the chance?

Hope the article was useful to you. We will be right back with another exciting piece of information. Till then take care and…

Work safely!