High visibility clothing, also known as Hi-Vis work wear is the crucial requirement for mainly industrial sites for workers who need to be recognized from far away. Workers who work near traffic points, cranes and other motorized vehicles, who undertakes nighttime operations in poor lighting conditions, are the ones who require to wear these high visibility clothing.

The main significance of high visibility clothing is to make the wearer clearly visible from quite a distance far from all angles in order to prevent accidents while they are working. These clothing encompasses t-shirts, vests, jackets and trousers and should have EN ISO 20471 certification.

They fall under 3 classes: class 1, class 2 and class 3 high visibility clothing, wherein class 1 stands for lowest visibility, class 2 with intermediate level of visibility and class 3 with highest level of visibility.

In this article, I am going to talk in details about all the 3 classes of high visibility clothing and tell you which clothing comes under which class and when and where to wear them.

Let’s begin!

What is EN ISO 20471 standard for HI-VIS clothing?

What is EN ISO 20471 standard for HI-VIS clothing?

This is an international standard for HI-VIS clothing made for the safety requirements of any high risk situations and which elaborate the test methods of HI-VIS workwear. The EN ISO 20471 sets the requirements for retro-reflective materials, background materials and combined performance materials.

The certification is based on the minimum requirements of the 3 classes as follows:

| FLUORESCENT MATERIAL | REFLECTIVE TAPE | |

| CLASS 1 | 0.14 sqm | 0.10 sqm |

| CLASS 2 | 0.50 sqm | 0.13 sqm |

| CLASS 3 | 0.80 sqm | 0.20 sqm |

When and where to wear which class of clothing?

Based on the risk factors of the workplace and also based on the data provided above, you need to measure the distance of visibility your workers would need and then assign the particular class of clothing to the workers. For example, if your workplace is too risky and needs visibility from a long distance away, the fluorescent material should be visible 0.80 sqm away and the reflective tape should be 0.20 sqm that is you will need class 3 high visibility clothing.

3 Classes of High Visibility Clothing

1.) High visibility class 1 clothing:

These are the lowest visibility clothing. Items under this class include hi-vis trousers which are worn separately from other high visibility garments.

2.) High visibility class 2 clothing:

These are the intermediate level of visibility items. Items under this class include hi-vis sleeveless vests.

3.) High visibility class 3 clothing:

These are the highest level of visibility clothing. Items under this class include hi-vis jackets and hi-vis sleeved vests.

When should you replace or what is the life span of high visibility clothing?

The high visibility clothing can be used up to 25 washes. In other words, the high visibility clothing should last you for approx 3 months. One thing to note is that you should not wash your high visibility clothing too often nor should they be washed less often. Washing them too often will decrease their fluorescent level of visibility and washing them less often would lead to dirt build up, which in turn again would decrease the visibility.

What are the 3 components of Hi-Vis clothing?

The 3 main components of high visibility clothing are as follows:

1.) Fluorescent Materials:

Fluorescent materials serve in two purposes: they are so designed to increase the visibility during day light when there is enough sunshine outside and also during night time, when nothing else is visible.

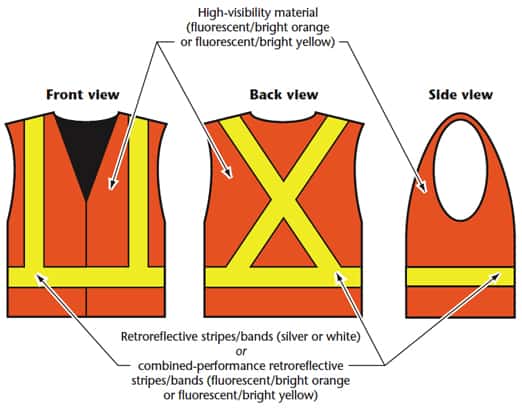

2.) Reflective strips:

Reflective strips are materials which require a light source to create a reflection or to be more precise, to create retro-reflection. These are essential for darker hours of the day as well as for the night time. There are many types of angle strips available, the most common among them being the glass beads reflective. These are mostly worn around the legs and sleeves and are generally worn with long-sleeved garments, bomber jackets, Hi-Vis trousers and Hi-Vis fleeces.

Reflective Glass Beads

3.) Contrast materials:

These materials are especially used for those parts of the clothing where dirt accumulation is quick as these are less sensitive to dirt than the fluorescent materials and the reflective strips. These are generally made with darker color pigments which are less sensitive to dirt. These materials are generally used in the sleeve ends, across the abdomen area, ankle and knee sections etc. The types of clothing used are Hi-Vis fleeces, Hi-Vis trousers, jackets and waterproof trousers.

Requirements of high visibility clothing:

According to the EN ISO 20471 standard, the high visibility clothing should comply with the following requirements:

1.) The high visibility clothing should be exposed to the fullest length and breadth of the material. In other words no normal clothing should restrict the visibility of high visibility materials. For example, you should not tuck in high visibility vest under your trousers or should not wear a non high visibility jackets over the high visibility sleeveless jackets.

2.) The colors of the high visibility clothing should be: fluorescent red, fluorescent orange and fluorescent yellow.

3.) The high visibility clothing materials should have a minimum certified tensile strength, dimensional stability and thermal resistance.

4.) The bleeding that is the blending of fluorescent color with the darker colors in the making of the high visibility materials should be in such a proportion that the fluorescent color should overpower the darker colors in order to remain prominent from a long distance.

Where to use which class of high visibility clothing?

Well, the places to wear the particular class of high visibility garments are categorized below:

-

-

- Type O (off road)

-

-

-

- Type R (roadway)

-

-

-

- Type P (public safety)

-

Type O:

Type O:

Type O includes:

-

-

- Workers who retrieve shopping carts from parking areas

- Those who work in oil and gas extraction sites, mines and refineries

- Those who are exposed to warehouse equipment traffic

-

Type O environments require wearing CLASS 1 high visibility clothing.

Type R:

Type R:

Type R includes:

-

-

- Those who work in toll gates or parking areas

- Those who work as school crossing guards

- Those who work as airport baggage handlers and as ground crew

- Those who work in roadway construction sites

-

This type of environment requires wearing of CLASS 2 & CLASS 3 high visibility clothing.

Type P:

Type P:

Type P includes:

-

-

- Who work as accident site investigators

- Fire-fighters

- Emergency wards

- Those who work in law-enforcement genres

- Road closure departments

-

This type of environment requires the wearing of CLASS 2 & CLASS 3 types of high visibility clothing.

Visibility index (distance of visibility) of 3 types of environments:

| Type R | Type P | |

| Class 1 | – | – |

| Class 2 | 775 SQ. IN. | 450 SQ. IN. |

| Class 3 | 1240 SQ. IN. | 775 SQ. IN. |

Before we say Good Bye:

Hope this article was able to give you at least some insight into the 3 different classes of high visibility clothing.

If you are the owner of the workplace, you need to study the data provided in the article, wherein you need to identify the type of your environment and understand the requirements of the class of clothing and select class 1 class 2 or class 3 type of high visibility clothing according to the data.

Well, that’s all for today guys. We will be right back with another informative piece of writing. Till then take care and…

Stay safe!