Cowboy boots are the most costly of all boots since they always cost a few hundred dollars. Yes, they are one of the most expensive boots in the world, but what makes them so damn expensive?

Let’s investigate!

A nice pair of cowboy boots may cost anywhere from $200 to $1,000 or more, depending on the manufacturing process, style, material, brand, stitching, and whether they’re custom made which will cost you way more.

Cowboy boots are pricey due to their genuine leather, experienced craftsmanship, and intricate design. They are expensive due to their distinctive characteristics too. You are paying for the material, quality, style, and longevity of cowboy boots.

Aside from that, how, where, and what the cowboy is constructed of ultimately determines the cost of it.

And before we understand what affects the cost of these boots, let us first understand the making of a cowboy boot.

1.) Raw materials

Calfskin is the most often used material for cowboy boots since it is both easier to work with and more durable. The majority of calf skins used in bootmaking are imported from Europe rather than the United States.

However, cowboy boots are fashioned from a variety of materials, including calfskin, pigskin, horsehide, and kangaroo skin.

2.) Cutting the pieces

After selecting the leather, the process of creating the upper half of the boot begins by cutting off the individual components. In custom (bespoke) shops, this is done by hand, but in factories, it is done with metal dies that work like cookie cutters.

The top of a boot is divided into three sections: the top that covers the top of the foot, the rear of the heel, and the bottom that fits around the bottom of the shins.

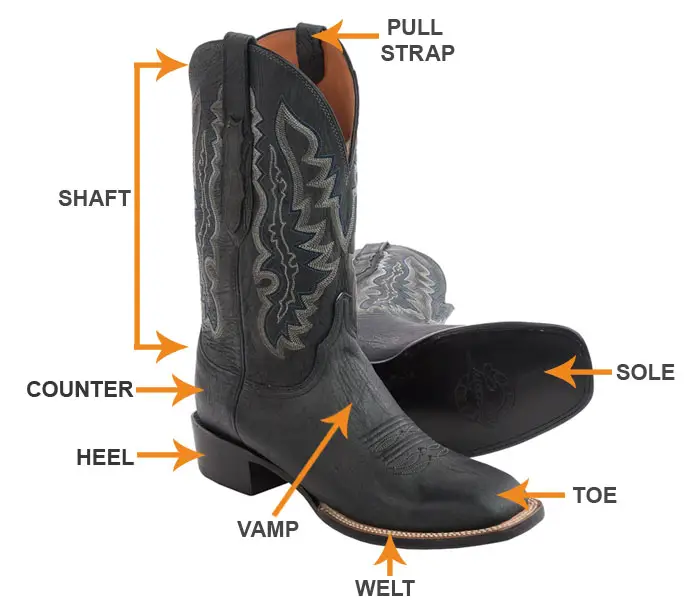

These are known as the vamp, counter, and uppers, in that order.

• Vamp- It is similar to the top and sides of a regular shoe, but it is one piece rather than multiple, with no lacing holes or a separate tongue.

• The uppers- They are made in two sections, one for the front and one for the back, and are meant to be joined at the sides. The lining for the interior of each of these pieces is cut out and put into place at this point.

3.) Designing

If the boot will have embroidered ornamentation and designs, it will be done before the components are combined. The design is designed on a paper pattern or stencil and then highlighted with a succession of little holes in bespoke shops.

This stencil is applied to each piece and then dusted with a marking agent so that the design may be followed by a sewing machine operator and any extra colors required by the pattern are dyed into the leather at this point.

4.) Putting on the insole

Attaching the insole to the vamp and counter is the first step in constructing the bottom. The insole is the section of a shoe or boot that you see when you look down inside it.

The vamp and counter are then hammered over the insole into the last, beginning at the toe and going around on both sides towards the rear.

The welt is then sewed onto the vamp and insole, which has been hanging on the rear of the counter since the top was initially manufactured. The boot is nearly finished, with only a heel and a sole remaining.

5.) Finishing process

The boot’s ultimate look is determined by the finishing procedure. Seams are trimmed, and loose threads are clipped. If required, final colors are added before the boot is waxed and polished.

The boots are examined for quality at this point, however quality control requirements differ between factories and bespoke shops.

In a bespoke shop, the way a boot fits a certain customer distinguishes an authorized product from one that may need to be altered or rejected.

However, the number of stitches per inch is crucial in both types of manufacture, as is the quality of the leather and the strength of the welt.

Factors influencing the price of cowboy boots

Cowboy boots are now mass-produced in massive quantities, and the patterns and embroidery options are virtually limitless owing to improved sewing machines and a vast range of materials available.

Despite this, if you want to go for an authentic purchase, you’ll want to fly to Texas or Kansas for a master-crafted and long-lasting cowboy boot that evokes the timeless allure of the past.

1.) Type of leather

Cowboy boots manufactured from exotic leather, such as caiman, lizard, stingray, shark, and so on, are often far more expensive than cowhide boots. Because these materials are more difficult to get by and in limited supply.

Cowhide is commonly used in the creation of cowboy boots since it is more easily accessible and reasonably easy to deal with. In terms of price, these boots are typically more cheap for the buyer.

2.) Location of their manufacturing

Machine-made cowboy boots will almost probably be less expensive than handcrafted cowboy boots. This is the primary explanation for the disparity in manufacturing costs across three continents.

Cowboy boots are largely created by machines in Asia. With such machines, hundreds of cowboy boots may be manufactured in a single day while spending very little on labor.

Furthermore, Asian labor expenses are far cheaper than those in Europe and America. As a result, production expenses may be kept to a minimum.

Cowboy boots made in the US are not totally manual. Cowboy boots are built from both handcrafted and machine-made components. In general, it requires more work than in Asia.

Cowboy boots from Europe, on the other hand, are more expensive because the majority of them are fully handcrafted.

3.) Brand

The cost of a particular pair of cowboy boots is also determined by the popularity of the brand and the experience of the bootmaker.

Custom crafted cowboy boots typically cost between $1500-$3500, with choices such as exotic leathers and complex embellishments increasing the cost.

A pair of regular cowboy boots that aren’t custom made can cost anywhere from $100 to 1000$.

4.) Design

A cowboy boot produced in Europe will normally cost more because they are all handcrafted. Boots manufactured in America, on the other hand, may use a combination of machine and manual labour throughout production.

To generate vast volumes of machine-made cowboy boots, Asian manufacturers often employ leather or a fake material. Although these boots are less expensive and mass-produced, it doesn’t imply they’re all horrible.

5.) Enhancements

Enhancing the look of the boot by embroideries or other items on a cowboy boot will be one of its most distinguishing aspects. Cowboy boots can be used to complement décor inspired by one’s culture, custom, area, and other factors.

You may custom request unique embroidered patterns and designs from your preferred manufacturer, however, keep in mind that regardless of the quantity of ornamental components, there will normally be three aspects that will identify the maker of your boots.

The tongue shape, toe stitching (also known as the medallion), and cording design at the ball and toe are all distinguishing characteristics of a cowboy boot maker.

6.) Size

When shopping for shoes, keep in mind that the price may vary slightly based on the size of the shoe. When looking for an excellent pair of cowboy boots, you will most likely notice a larger price difference.

The unique tall-shaft construction and appearance of a cowboy boot necessitate special attention and care. As a result, larger-sized cowboy boots require more leather or animal skin, sewing, and labor.

To conclude, cowboy boots are well worth their price due to their durability and strength.

However, their price range is vast because of the variety it offers.

It totally depends on you whether you want to go for custom made boots, that can cost you a lot, or you want to buy regular brand boots, that is reasonable.

Whatever you decide, you can rely on this guide to be your one-stop shop for making an informed decision.