ANSI stands for American national standards institute and ANSI 107 (American national standard for high visibility safety apparel and accessories) is a standard established by ANSI that provides guidelines regarding the selection and the use of high visibility safety apparels (HVSA).

ANSI 107-2015 is the latest standard that summarizes the main provisions of the standard which includes basic design requirements and minimum performance criteria for HVSA (high visibility safety apparels. The 2015 revised version of the standard combines both the standards of 107 & 207 into a single document. According to the new version, garments are separated into “3 TYPES” viz off-road TYPE O, roadway TYPE R & public safety TYPE P.

The main focus areas of ANSI 107-2015 are:

-

-

- The design of the HVSA

- The requirements of the background color and materials

- The combined performance of the retro-reflective materials

- The requirements for photometric and physical performance of the retro-reflective materials

- The care labeling of the garments of each type

-

Now let’s look into the above points in details:

The Design of the HVSA:

ANSI 107-2015 specifies the design guidelines for the high visibility garments which include the photometric requirements, the colors to use, the placement, and the minimum amount of component materials required in order to enhance the visibility of the garments for the safety of the workers in hazardous situations.

ANSI 107-2015 specifies the design guidelines for the high visibility garments which include the photometric requirements, the colors to use, the placement, and the minimum amount of component materials required in order to enhance the visibility of the garments for the safety of the workers in hazardous situations.

The selection of the colors, components and materials should be made according to the type of hazard and the safety requirements for the particular purpose.

Background and combined performance colors:

For background and combined performance materials three different color codes are available: fluorescent red, fluorescent yellow-green and fluorescent orange-red. The color used in the garment must be in contrast to the rest of the environment and the surrounding equipments.

Types of Garments

Garments are divided on the basis of 3 types: TYPE O, TYPE R & TYPE P. types basically refers to the areas of use of the garments which are as follows:

TYPE O:

O stands for off-road areas. Type O high visibility garments should be worn by workers who are not bound by MUTCD 2009 to wear high visibility safety apparels during work. This is because workers in the off-roads areas do not have the danger of struck by vehicles while working. Still they need safety apparel in order to be visible while work to avoid unpredictable dangers.

TYPE R:

R stands for roadside. This type of garments are worn by workers who are exposed to high roadway traffic and also who work in environments with moving vehicles or equipments.

TYPE P:

P stands for public safety. This type of high visibility safety apparels are worn by workers in the fire fighting crew, police, and the EMS personnel.

The placement of the retro-reflective material:

You must first learn about the different classes of high visibility safety apparels according to ANSI 107.

According to the standards, class 1 class 2 and class 3 high visibility safety garments must achieve the following:

→ It must have a retro-reflective band width that is appropriate for the particular class of garments.

→ It should provide 360 degree visibility along with horizontal gaps of 50mm or so.

→ The garments without the reflective material encircling the sleeve area must have 150 cm square of reflective material in the shoulders in order to provide 180 degree visibility of the wearer.

→ In the torso, trousers and sleeve areas there should be an appropriate separation distances of horizontal and vertical bands.

The requirements for the background and combined performance materials:

In section 8 of the ANSI 107 standard, there are mentioned specifications for colors, fabric strength, brightness and moisture resistance after the conduction of several exposure tests.

In section 8 of the ANSI 107 standard, there are mentioned specifications for colors, fabric strength, brightness and moisture resistance after the conduction of several exposure tests.

→ The background materials must be tested for colorfastness after the perspiration and crocking tests.

→ The background and combined performance materials must be tested for chromaticity that is color, luminance that is brightness before preconditioning and then for colorfastness after performing the standard cleaning process and the Xenon or UV light exposure.

→ Some other tests include: test for shrinking after the washing and dry-cleaning process, test for tensile strength, test for tear resistance and also the bursting strength of woven and knitted material.

→ If the garment would be used for rainy conditions then tests for water repellent, water proof and water resistance must be carried out.

The requirements for photometric and physical performance of the retro-reflective materials:

The standard specifies the following:

1.) The photometric performance must be defined with a combination of 4 observations, 4 entrances and 2 orientation angles.

2.) Each and every material should meet the brightness requirements after performing the tests for abrasion resistance, variation in temperatures, flexing, rainfall influence, laundering, folding at cold temperatures.

3.) The combined performance material should also meet the brightness factors after the Xenon or UV exposure test.

Care labeling, instructions and marking for use:

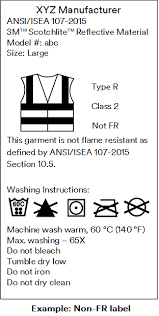

Care labeling is done only after the above mentioned tests are performed and the garments have passed for the specific tests. Care labeling for different types and classes would be different as mentioned in the sections 11 to 13 of the ANSI 107 standard.

Care labeling is done only after the above mentioned tests are performed and the garments have passed for the specific tests. Care labeling for different types and classes would be different as mentioned in the sections 11 to 13 of the ANSI 107 standard.

The markings include the following points:

-

-

- The name of the manufacturer or any other means of identification

- The item number of the product

- The specific style of the product

- The size of the garment

- The ANSI standard name including the year, for example: ANSI 107-2015

- Whether the garment is “FR” flame resistant or not

- The maximum number of washes after which the garment should be discarded

- Any pictogram indicating the type, class and level of performance of the garment

-

Before we say Good Bye:

There is a difference in the standards of ANSI 107-2010 and ANSI 107-2015 and you have to be sure which standards are required by your workplace, though the 2015 version is the latest one and that is the reason we have written about it.

Hope the article was informative and could give you a detailed knowledge of the standard. If you have further queries, you can ask us through the comment section below and we would be happy to answer you.

That’s all for today! Do not forget to check our article on the details of the types and classes of safety vests.

Until we meet soon, take care and…

Work safely!