The federal government of the United States establishes safety guidelines in regard to the decrease in on the job injuries within the workplace. OSHA, within the U.S Department has adopted certain safety eyewear standards established by ANSI.

According to the ANSI standards, safety eye glasses are of two types: prescription and non-prescription eye glasses. The non-prescription lenses are generally structurally weaker and thinner than the prescription lenses which can withstand more impact. The lenses in the safety eye glasses must have higher impact resistance capacity and the frames must be stronger and heat resistant and also prevent lenses from being pushed into eyes in case of accidents.

In this article, I am going to tell you in detail about the two types of eye glasses, their standards, ratings and the testing standards, types of safety lenses at work and which one would be the best for you.

So, without any further delay, let’s proceed…

What are safety eye glasses?

Safety eye glasses are a part of PPE (Personal Protective Equipment) that should be worn by workers in the job site to protect their eyes from hazards of the work environment. The safety eye glasses act as a shield to protect the eyes from any injuries resulting from sharp objects piercing the eyes, debris getting inside the eyes, sparks from fire damaging the eye sight, liquid chemical splashes, etc. they are used in various fields such as electrical works, welding, chemical laboratories, wood mills, sports, swimming, etc.

The frames of the safety glasses are usually made of nylon and have side shields to protect flying materials entering the eyes from the sides.

Safety eye glasses differ from the regular eye glasses in the aspect that safety eye glasses must have to conform to much higher standards of impact resistance which applies to both lenses and the frames of the safety eye glasses.

Material of the Lenses of Safety Eye Glasses

Safety eyewear is generally made of any of the following materials, but mostly polycarbonate ones are used widely:

1.) Polycarbonate: These are the most impact resistant of all the lenses. They have built-in UV radiation absorption properties and are scratch resistant. They are extremely lightweight too.

2.) Hi-Vex: These lenses also impact resistant to a great extent and have 100% UV filtering. They are lightweight and coated with all surface treatments.

3.) Plastic (CR39): These lenses are resistant to solvents and pitting and are about half the weight of glass lenses.

4.) Trivex: These are more impact resistant than plastic and less than polycarbonate and have UV radiation absorption properties.

5.) Glass: These are heavy lenses and lose impact resistance capacity when scratched.

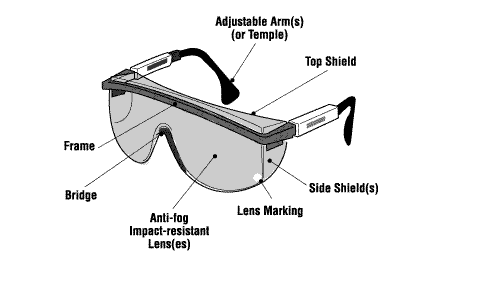

Parts of Safety Eyewear and their Usages

A safety eyewear is made of the following parts:

1.) The frame: The frame is the part which supports the lens and the other parts of the eyewear. It is generally made of nylon or plastic.

2.) The lens: Lens is the part through which you see. I have already mentioned the different types of lenses above. Also, there can be added a reflective coating on the lens to protect from UV rays.

3.) Top shield: The top shield is the part which falls on the eyebrows and this part prevents the entry of dust particles and other debris from falling from above.

4.) Adjustable arms: The adjustable arms rest over the ears and support the frame of the eyewear. They have adjustable screws to make it tight or loose according to your face shape.

5.) The bridge: The bridge of the frame rests over the nose to add as a support to the frame. It prevents the frame from slipping down while you bend down your face.

6.) Side shield: The side shields on both sides of the eyes prevent dust particles and debris from entering the eyes from the sides.

7.) Lens marking: There are different types of marking on the lens based on which category they fall into, for example whether they are prescription or non-prescription. I will be talking about all of them in the section below.

Ensure Proper Fit of the Safety Eye glasses

You must check the following fitting rules before buying your safety eye glasses:

√ The eye glasses should cover from the eyebrow to your cheekbones and across from the bridge of the nose to the bony area on the outer side of the eyes.

√ The gaps between the edges of the eyewear and the face should be minimum.

√ The safety eye glasses should fit right over the temples and the over the ears comfortably and should not hurt your ears.

√ You should be able to see clearly through the safety glasses in all directions without any difficulty.

√ In the test for durability, the safety frames must also pass the flammability resistance test and the corrosion-resistance test.

What are the ANSI standards for Safety Eyewear?

The ANSI standards are as follows:

1.) First, the lenses are tested separately for the basic impact tests.

2.) Then both the lenses and the frames are tested together for high impact.

3.) Prescription lenses have to be of 3mm thickness to resist high impact.

4.) In the basic impact test (the drop ball test), a 1” diameter steel ball is dropped on the lens from a height of over 50”. In order to pass the test, the lens must not crack, break or chip.

5.) In high impact test, a quarter-inch diameter steel ball is shot at a high velocity of 150 feet per second. In order to pass the test, the lens must not crack, break or chip.

Assessing Ratings of Safety eye glasses

Safety eye glasses generally have the following marks either on the lenses or on the frames:

The Plus (+) mark:

This mark will signify that the prescription lens has passed the high impact test.

The “V” mark:

This mark indicates that the lenses are photochromic.

The “S” mark:

This mark indicates that the lenses have special tints. The tint densities for works such as cutting, brazing, welding and soldering range from 1.5 to 3.0 and for electric arc welding it ranges from 10 to 14.

According to the ANSI Z87.1-2003 standards, the following marks should be there on the frames:

Non-prescription safety eyewear:

-

-

- Z87 for basic impact

-

-

-

- Z87+ for high impact

-

Prescription safety eyewear:

-

-

- Z87-2

-

Which Safety Eye Glasses Should You Buy?

Well, it all depends on the type of job you are into. Some jobs require the use of high impact resistant safety eyewear, whereas the others require the basic impact resistant ones.

If you work in the following fields, you should definitely opt for the high impact resistant glasses:

-

-

- Plumbers and pipe fitters

- Daily laborers

- Welding

- Millwrights

- Independent contractors

- Electrical departments

-

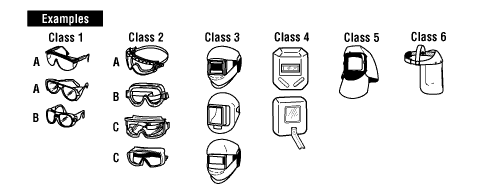

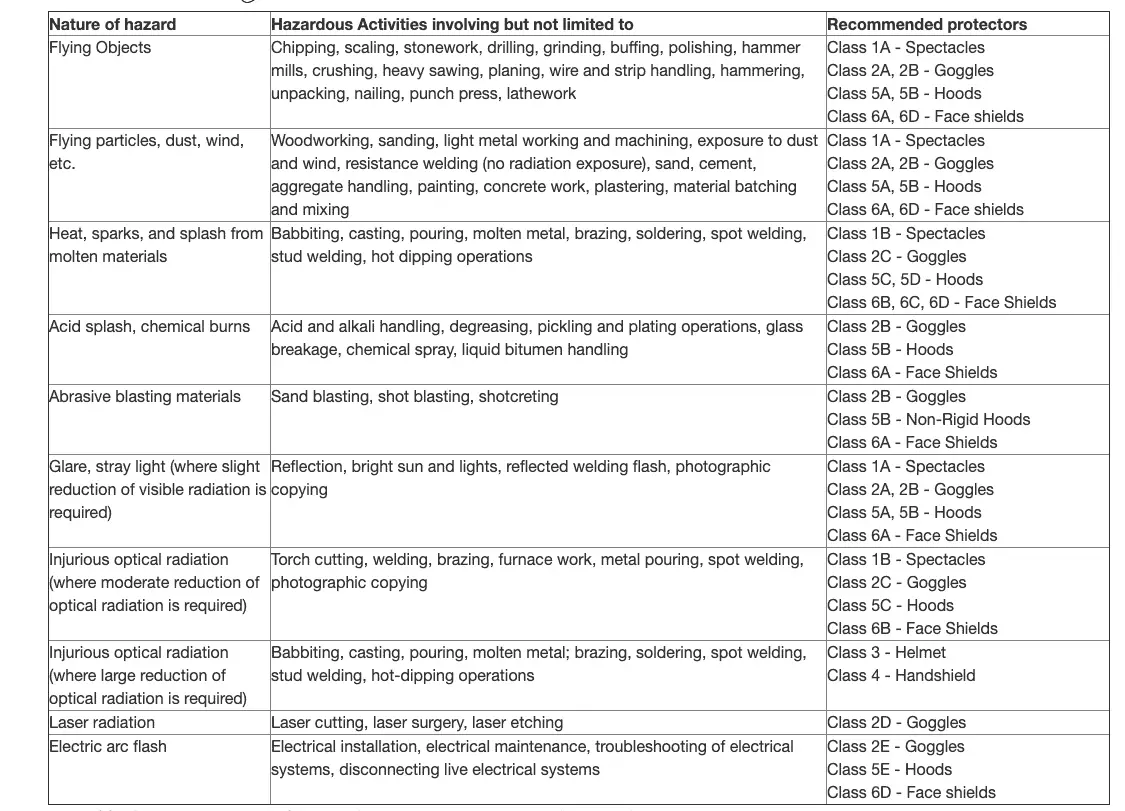

Also you check the following table to understand better which safety eye glasses would be apt for your job:

From: CSA Standard Z94.3.1-16 Guideline for selection, use and care of eye and face protectors

It’s time to bid Adieu!

Before buying your safety eye glasses you must be aware of the requirements of your job site for example a stone cutting, wood cutting job will require safety glasses of lighter tints and high impact resistance and that electrical work will require a darker shade, basic impact resistance and flame resistance.

That’s all for today’s article. I hope the article was useful to you.

Have a great day ahead! Stay safe and…

Happy safety eye glasses shopping!