Heating the warehouse is a necessity that, at the same time, causes a great deal of difficulty as to how to implement it successfully.

It’s challenging to keep your warehouse and employees warm during the winter when loading doors are often opened and closed throughout the day and night.

This could result in an uncomfortable work environment. However, there are ways to counteract the cold in your warehouse throughout the winter by insulating the doors and windows, providing adequate shelving, and circulating and zoning heat by installing a heater system.

Certain elements, such as the layout of your warehouse, should be considered before selecting the appropriate heater system.

This article will provide you with the most important and valuable information on how to keep your warehouse and yourself warm.

What is the Need for Warming?

As the definition goes on, a warehouse is nothing but a well-planned space for providing efficient storage and handling of goods and materials.

Maintaining such a facility allows us to manage resources and control and supervise the incoming and outgoing flow of goods.

So, a warehouse is a necessity for any business that benefits from selling physical goods or purchasing products from a wholesale market.

As you can see, warehouses hold goods that generate profit for the product-based companies. It is essential for keeping the warehouse under climate control as per the requirement of the products.

Let’s focus on keeping the warehouse warm. It is extremely important to keep the warehouse warm as the products must be kept at a specific temperature so that it doesn’t get deteriorated or damaged.

The Health and Safety Executive asserted that the temperature in workplaces should be at least 16oC and in environments where a lot of physical activity is involved, here temperature can drop to 13oC.

So, this directly shows us that in order to create the perfect environment where both your employees and products and equipment can thrive, it’s necessary that your warehouse is properly heated to reasonable temperatures.

However, heating warehouses can be a tricky business because heating a space which is so vast might seem like an impossibility yet a very expensive possibility.

However, this cannot be a reason for not providing sufficient heating for both your employees and the products that you are storing. This post will give you detailed tips for warming your warehouse.

Seven Effective Tips To Warm Your Warehouse

1.) Insulate Windows and Doors

Windows and doors are the first reason that cause heat loss as they were closed and opened frequently for shipments and deliveries, thus exposing the warehouse to the coldness.

To resolve this, first check for leaks in the seals on your windows and doors, as seals will deteriorate in due time, requiring immediate replacement.

Second, install insulated, double-pane windows. As the air is the best insulator, capturing a layer between two panes of glass can limit heat loss.

Finally, installing a vinyl strip curtain on the loading dock doors can prevent cold air from entering the warehouse during long durations of loading or unloading.

2.) Circulate the Air

We all know that heat rises when a building has high roofs and in the case of warehouses which do have higher ceilings than other normal buildings, warm air will naturally congregate at the top, leaving the goods and employees down below in the cold air.

One effective way to fix this is to circulate air and this can be done by installing a suspended fan. This will push hot air down and will mix with the cold air making the temperature of the air more even throughout the building.

3.) Zone Your Heating

Zoning the heat is as effective and important as circulating the air. There will be different spaces like office space and temperature- sensitive products or equipment that need different climates.

Heating required for office space where the employees are equipped most of the time is different for the zones where active loading and unloading happens. The former needs more heating that the latter as in this zone people are working enough to get them sweat.

Heat zoning can be done with the space heaters, which is more cost-effective than just maintaining high temperatures for the entire building.

However, never forget the places and products that needed to be placed in cold conditions. Provide adequate temperature in such places so that it doesn’t get spoiled.

4.) Using a Programmable Thermostat

A programmable thermostat adjusts the temperature based on a series of pre-programmed parameters that take effect at various periods throughout the day.

When staff are not present, there is no reason for a warehouse to be heated unless the equipment requires it. Programmable thermostats are programmed to provide heating to the warehouse soon before employees arrive for the day and turn it off as the day progresses.

This can be done through an app on your computer or phone to set up a schedule or make modifications to the setting. They may also react to the weather and adjust automatically by adding more heat when it becomes cold outside and turning it down when it gets hot.

5.) Provide Appropriate Shelving

The warmth produced by your warehouse heating system will only be effective if it is permitted to fill your warehouse; if there is any obstruction, the heat will not be able to spread throughout the space.

Some potential barriers include: shelving, equipment, waste bins or containers, as well as tanks. If you can simply move the barrier, then you may have an easy solution.

If several vents are covered by shelves or huge pieces of equipment, it’s worth rethinking your floor plan and designing a new one that allows for more ventilation.

The right racking system will ensure the right heating. One way to provide appropriate shelving is having a custom engineered racking system which will be installed knowing the layout of your warehouse.

6.) Have a professionalised HVAC System

Consider hiring an HVAC specialist if you need to heat your warehouse but don’t know where to begin. A professional can conduct a “audit” of your warehouse, checking for leaks, hot and cold areas, zoning opportunities, and other issues before offering a comprehensive solution that saves you money while keeping your employees warm.

It’s also a good idea to perform this once a year to keep your HVAC system working properly and avoid any potential outages.

7.) Install a Heater System

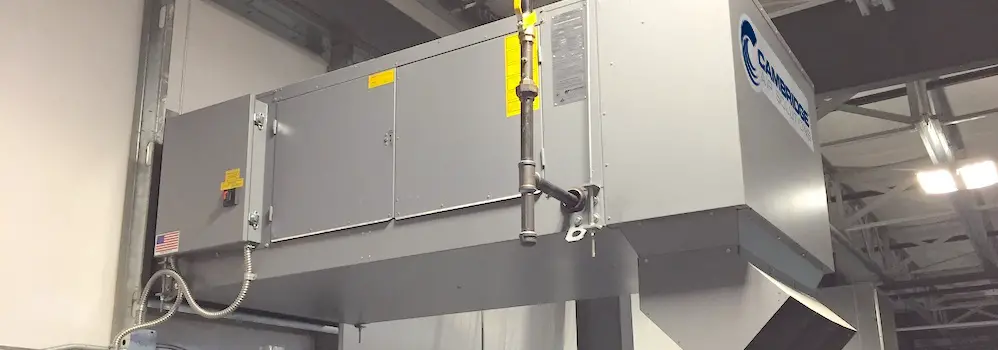

You have two alternatives for heating a warehouse: a warm air heater or a radiant heater. Warm air heaters heat an area by warming the air, whereas radiant heaters only heat the people and objects in their immediate vicinity.

A heater must be installed either to circulate air or to zone the heating. Warm air heaters are a superior choice for warehouse heating since they can disperse warm air uniformly over a broad area.

So, when it comes to selecting the best heating system, you must be aware of the most significant factors, which include:

1.) Heat Distribution: Take a look around your warehouse to see if there are any big impediments to the heat being dispersed equally across the facility.

2.) Racking: The problem with racking when trying to heat a warehouse is that it can prevent heat from being distributed evenly throughout the warehouse.

3.) Floor Space: The operation of some heating system solutions necessitates the use of floor space. If you’re already having difficulties finding floor space for your operations, the best warehouse heaters that can be put on the ceiling or the wall should be your first choice.

4.) Destratification: Destratification is the process of cycling warm air from the warehouse structure’s roof to the building’s inhabited floor space. Installing suspended fans on the building’s roof is a simple way to accomplish this.

See also: Best Shoes for Warehouse Work

Tips For Keeping Heating Costs Reasonable

Purchasing commercial heaters for warehouses is expensive when compared to the expense of operating other systems. Unfortunately, high energy prices are normalised as an unavoidable expense of doing operations in a warehouse.

But you should realise that there are a few strategies you can use to keep your heating bills within a reasonable range throughout the entire year.

1.) Work in Zones

Examine how your warehouse operates, paying special attention to the areas where your employees work and spend the majority of their time during the day.

Finding this will assist you in identifying areas of your warehouse that are used less frequently than others. This crucial information subsequently aids in the selection of the best warehouse heaters for the application.

These occasional-use zones can help you save money on your warehouse’s heating expenditures. Since employees won’t be spending much time in these zones, some of the best commercial heaters for warehouse buildings allow you to lower the temperature in these zones.

2.) Install Timed Controls

A timed control could be the ideal answer for making your warehouse more energy efficient. Some of the best commercial heaters allow you to program in timed controls that will turn the heating system on and off according to the requirement.

One example of timed controls is the programmable thermostat discussed in the previous section.

The greatest warehouse heaters will allow you to select operating hours when the temperature would be at a more pleasant level. Controlling uncontrolled heating expenses, especially in the midst of winter, with timed controls can be a huge help.

How To Warm Yourself In A Warehouse

Warming the warehouse helps to maintain the warmth of both human and material resources. However, having extra caution while working in warehouses during the winter season is always recommended because the warmth within the warehouse is insufficient to keep you warm.

For that sole reason there are some tips that you could use for warming your body.

1.) Wear Layered Clothing: this helps your body to control your body temperature by trapping the warm air between the layers; the layers then act as a good insulator.

2.) Put on Insulated Coveralls: wearing thermally insulated coveralls aids in protecting your whole body and will provide adequate warmth. This apparel will help protect you from illnesses that are prevalent throughout the winter months.

3.) Wear Beanies, Gloves and Footwears: wearing these additional gears will protect your other body which is not covered by the coveralls. Select high quality waterproof gears for working in a warehouse during the winter season.

4.) Take Breaks to Warm Up: In order to keep your internal temperature warm in a cold environment, your body will work even harder. Taking a break to warm up improves the body’s heat production, as does drinking warm liquids such as tea or coffee.

This will infuse you with warmth from the inside out. You can take a break and rest either in a heated office or breakroom.

See also: 9 Best Gloves for Warehouse Work for Men and Women

To Conclude

Just like wearing layered clothing and insulated coveralls for protecting yourself from the cold, the goods and other resources in the warehouse needed to be warmed.

So, the goods are not damaged. The provided information in this writing is to aid you in choosing the best tip to warm your warehouse.

For that the first step is always to identify the characteristics of your warehouse, then apply the insights you gained from this information.

Following these tips is far enough to warm your warehouse, however it is always advised to have a HVAC professional to inspect your warehouse for strategizing better solutions.