Hard hats does the great job of protecting your head from any injury from falling objects or your head hitting on any hard surface. Therefore, the hard hat itself has to be made of such material so that it can withstand the pressure and impact of the objects while saving your head from the injuries.

The most reliable materials till date trusted in the making of hard hats are Kevlar and carbon fiber. But the question is which one is better than the other? While Kevlar is stronger than carbon fiber, on the other hand carbon fiber is denser and stiffer than Kevlar.

In this article I am going to tell you in details about both the materials so that you can make the right choice of your hard hat!

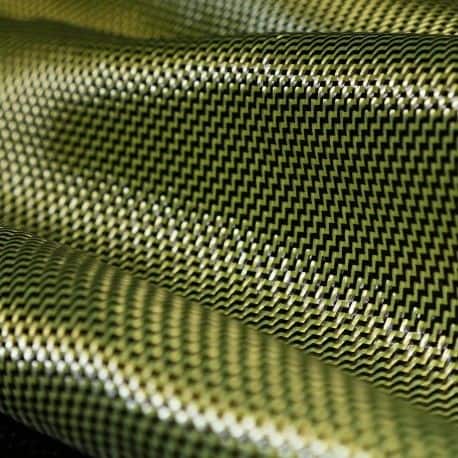

Kevlar safety hard hats

Kevlar is actually a synthetic fiber that falls under aramid fiber’s group and this group’s most unique feature is that they are heat resistant.

Kevlar is actually a synthetic fiber that falls under aramid fiber’s group and this group’s most unique feature is that they are heat resistant.

Kevlar has high tensile strength and therefore it is used in the making of several items such as: work boots, protective equipment’s, gloves, sealants, optical cable, tires of cars, brake pads, heavy industry items, etc.

Kevlar aramid is generally used for making equipment’s which require high performance, light weight, high strength, damage resistance, stiffness, and resistance to fatigue, damage and rupture.

Kevlar is not reactive or sensitive to electron radiation but sensitive to UV radiation. The tensile strength of Kevlar is 8 times greater than that of steel wire.

Unique characteristics of Kevlar:

Kevlar displays the following unique properties:

-

-

- It has a very low stretch

- It is an excellent fatigue resistant

- It does not melt but will decompose between 800 degree F to 900 degree F

- It has a very high strength to weight ratio

- It does not shrink

- It has good chemical stability

- It has high abrasion resistance

- It has good performance over a wide temperature range

- It has the least catastrophic failure mode

- Kevlar is 8 times more impact resistant than ABS

- It is 15 to 20% lighter than ABS

- It is 12 times more rigid than ABS and 30 times more rigid than nylon

- It possesses great durability

-

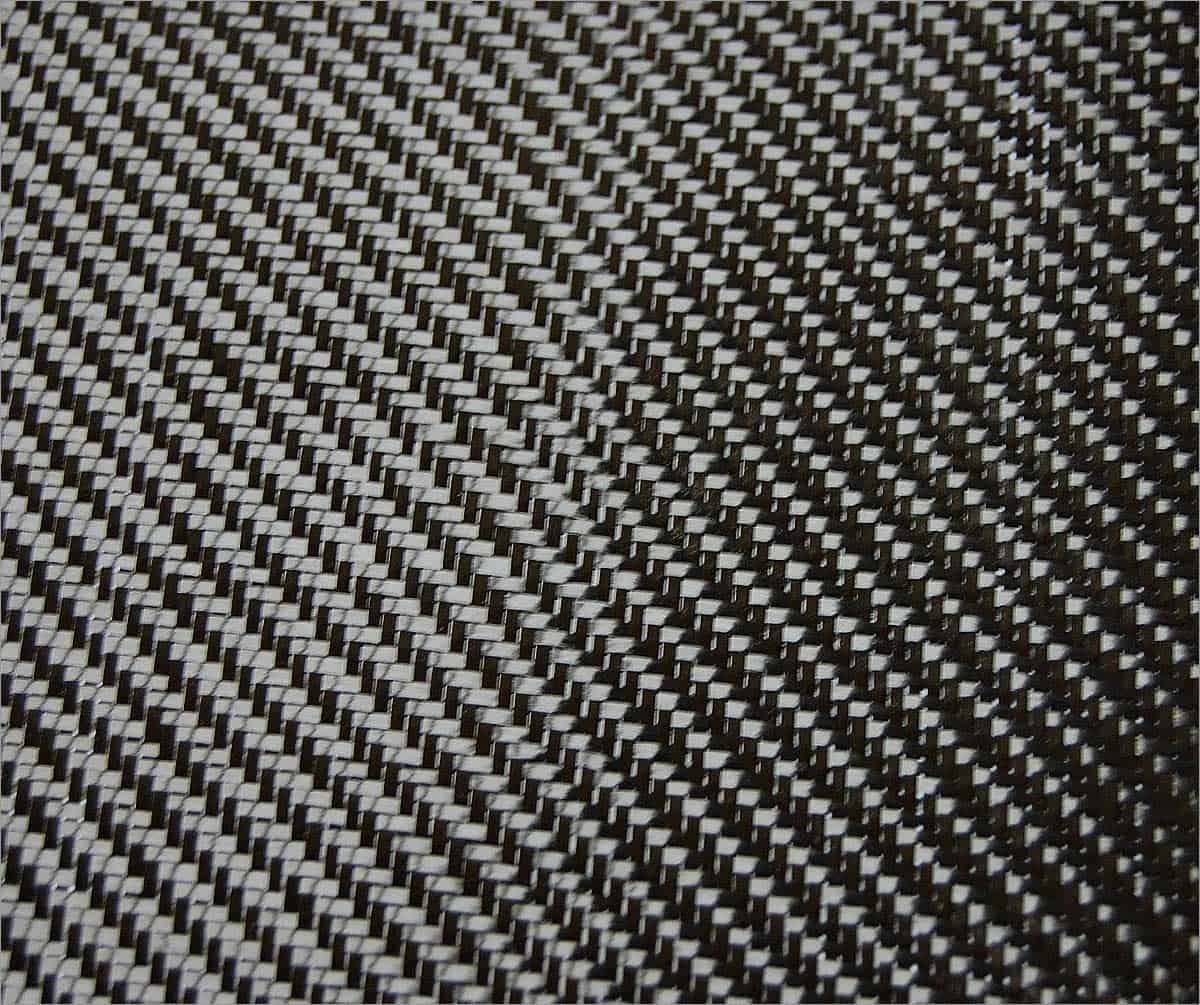

Carbon Fiber

Carbon fiber is made up of carbon atoms that are organized into crystalline structures. It has very high stiffness and strength and has one of the highest strength to weight ratio that is even higher than steel and titanium.

Carbon fiber is made up of carbon atoms that are organized into crystalline structures. It has very high stiffness and strength and has one of the highest strength to weight ratio that is even higher than steel and titanium.

Due to its high performance, carbon fiber is used in a variety of fields in the making of several equipments such as: construction, medical, electronics, defense, aerospace, industrial machinery, robotics, welding fixtures, components of bicycles, high end motor sport applications, CMM fixtures, etc.

Unique characteristics of carbon fiber:

Carbon fiber displays the following unique properties:

-

-

- It is used as metal replacements where there is an issue of weight saving

- Both carbon fiber and aluminum have equal yield strength and fails at the same strength. But while aluminum plastically deforms when load is applied, carbon fiber returns to its original shape once the load is removed

- Carbon fiber is corrosion resistant

- It is heat resistant too

- It’s ideal loading is constant that is it can support a known force all the time

- It is 25 times more rigid than ABS

- It is 8 times ore stronger than steel

-

Kevlar versus carbon fiber

Before understanding the difference between both the materials, you need to understand a few terms:

Ultimate tensile strength refers to the strength of the strength of the material until it breaks when outside force or load applied to it and this forms the basis of deciding which material you should use in making your product.

Calculating the stretch of the material is known as the stiffness. It is the ability of the material to resist deflation or deformation. It detects how far the material cannot be deformed or bent when a force is applied to it.

But stiffness and strength are not related at all because a very strong material might not be stiff or a very stiff material might not be very strong.

Next comes elongation. Elongation refers to how far the material will stretch before it breaks.

Difference between Kevlar and carbon fiber:

-

-

- Kevlar is a bit more stronger than carbon fiber

- But carbon fiber is incredibly stiffer than Kevlar

- Carbon fiber is dense than Kevlar

- Kevlar is the strongest in tension

- Kevlar has almost no strength in compression in the opposite direction

- Carbon fiber has almost no elongation

-

Kevlar versus carbon fiber hard hats

Both Kevlar and carbon fiber hard hats are ANSI compliant and are made of aerospace-grade Kevlar and carbon fiber.

Features of Kevlar hard hats:

-

-

- As Kevlar can resist bullets, the hard hats made from them can resist construction load very easily

- Kevlar hard hats does not burn or melt in high temperatures

- They are not affected by cold temperatures as well

- They are extremely light weight, estimated to be 40% lighter than standard hard hats

- They are really expensive because Kevlar is very hard to find

-

Features of carbon fiber hard hats:

-

-

- Carbon fiber hard hats are safe for electrical use as they have flexible electrical properties

- The structure of carbon fiber hard hats gives optimal level of comfort to the wearers

- They absorb external stress

- They prevent wear and dents

- They have good resistance against temperatures

- They have high anti-fatigue properties

- They are even more lighter than plastic hard hats

- They are ten times stronger than steel hard hats

- They protect the head from jerks

- They are shock-proof as well

-

It’s time to bid Adieu!

Nowadays most companies are making use of these two materials in the making of hard hats and exhibit unique and outstanding properties.

The level of safety offered by both is almost the same but yes in general terms, Kevlar is stronger than carbon fiber and therefore might resist more impact than carbon fiber, but as Kevlar is rare to find, it’s not a bad idea to go with the carbon fiber hard hats.

That’s all for today guys!

Have a great day ahead!