Despite increasing lookout for occupational safety and health during the past century, an estimated 317 million non-fatal occupational injuries and 321,000 occupation fatalities occur globally each year, making 151 workers sustain a work-related accident every 15 seconds according to ILO 2013 (International Labour Organization).

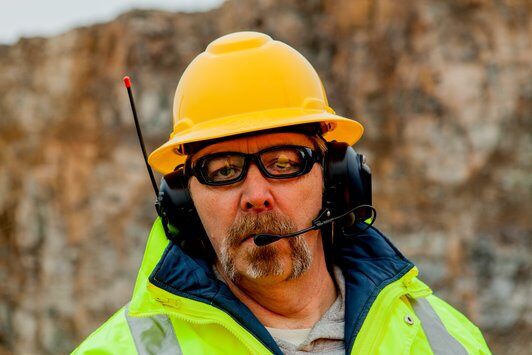

Most of these accidents take place due to the absence of safety gears worn by workers. One of the most important gears of safety is head protection accessory comprising of Full Brim Hard Hats and Cap Style Hard Hat. Moreover, head, being the most important part of a body, safety and protection is needed to be top-notch and uncompromising.

Since the chief objective of these hats is to provide protection, full brim hard hats are a notch above in this category as it gives 360-degree protection of face, ears, neck from sunburn, falling objects, electrical hazards and non-toxic splashes. In short, it offers complete head protection.

Both these hats are capable of providing an extra layer of safety to the workers. Therefore, in this article, you’ll find exact details about both Full Brim Hard Hats and Hard Caps, their differences, which one you should choose and why.

Comparison Table Between Full Brim and Hard Hats Caps

Though there are not many differences between these two types, still a comparison table is given below for better information:

| Features | Full brim hats | Hard caps |

| Material | High-density polythene. | Metals, fibreglass and sometimes rigid plastic. |

| Natural Protection | Provides all round protection to head and face from sunrays and rain. | Protection of head, forehead and partial face. |

| Way of Wearing | Brim should be pointing straight ahead. | Suspension should fit properly on the nape of the neck with the hood facing forward. |

| Comfort Level | Light weighted with superior retention and balance. | Light weighted, adjustable, with a secure fit. |

| Hazards | Provides additional protection to one’s head, face, ears and back of the neck. | Secures one’s forehead and half of the face only. |

| Users | Construction workers, electricians, utility workers, people working in steel factories and farmers. | Industrial, construction, factory workers etc. |

| Price | From $8 – $120. | From $4 – $335. |

Features of Full Brim and Hard Caps

1.) Material Used

-

-

- Full Brim Hard Hats are generally made of HDPE or High-Density Polythene.

- Hard hat caps were initially made of metals, later fibreglass was used and now it is rigid plastic.

-

2.) Colour Classification

Full Brim Hats are available in various colours on the basis of job profile like-

-

-

White for site managers, foremen, engineers and supervisors.

White for site managers, foremen, engineers and supervisors.- Yellow for general labourers and operators.

- Blue for carpenters, technical operators and electricians.

- Green for safety inspectors and sometimes new workers.

- Orange for signallers, lifting men and banks-man slingers.

- Red for fire marshal.

- Brown for welders.

- Grey for visitors on site.

- Black, also for supervisors.

-

Hard Hat Caps also possesses similar criteria regarding its colour on the basis of job profile.

3.) Protection From Natural Hazards

-

-

- Full Brim Hats prevents the face from the scorching sun, eyes from rain and dust and ears and neck from sunlight.

- Generally, the Cap style covers the forehead and half of one’s face from sunlight.

-

4.) Way Of Wearing

-

-

- While wearing Full Brim Hats one should keep in mind that the brim should be facing forward.

- When Caps style hard hat is worn, make sure that the suspension fits properly on the nape of the neck. It’s not at all cool wearing these caps with the hood facing backwards.

-

5.) Comfort Level

-

-

- Full Brim Hats give high level of comfort due to its lightweight along with its superior retention and balance.

- Hard Caps are generally stable, lightweight, adjustable with a secure fit.

-

6.) Protection From Injuries

-

-

- Due to the full brim all around the hard hat, they give added protection to one’s head, face, ears and shoulders.

- Hard Hat Caps are more like helmets with a hood in the front, securing one’s forehead and half of the face.

-

7.) Maintenance

-

-

- The suspension of Full Brim Hats should be modified, avoid putting stickers on it and replace it immediately after being struck by a strong blow.

- Hard Hat Caps should be cleaned regularly with warm water and mild soap rather than harsh detergent. Also avoid dropping, throwing or sitting on them.

-

Usage of Full Brim Hard Hats

1.) It acts as a perfect sun guard having 360-degree protection.

2.) It is capable enough for protecting your eyes, ears, face, neck and shoulders from getting sunburnt.

3.) It can easily resist electrical shocks, weather elements, non-toxic liquids and heavy objects falling overhead.

4.) It is quite beneficial for electricians, workers working at construction sites and steel-plants, utility workers, farmers etc.

Usage of Hard Hat Caps

1.) It has a small brim covering only the forehead and half of the face.

2.) It is available in two designs- Slotted and Non-slotted.

3.) The slotted ones include two apertures for holding flashlights and hearing- mounted earmuffs.

4.) On the contrary, the non-slotted ones don’t have any accessory holding space.

5.) It prevents rain water from running down your neck.

6.) It can resist electrical shocks, heavy objects falling overhead, splashes of non-toxic liquids and weather elements.

7.) Construction workers, steel workers, farmers, utility workers and electricians use these caps for their safety.

Pros of Full Brim Hard Hats:

→ Provides great protection against sun, heat, humidity, rain, glare and heavy objects.

→ One’s face and eyes are prevented from flying waste materials, with this hard hat on.

→ These hats safeguards one’s head from electrical shocks or burns, weather elements, impact of collision and in-noxious splatters.

Cons of Full Brim Hard Hats:

⊗ Although high quality wear-resistant materials are used to make these hats, still they are not everlasting.

⊗ They need replacement in every 5 years.

⊗ When exposed to high temperatures, chemicals and sunlight for a long period, their properties start breaking down.

⊗ It is quite advisable to replace these hats immediately after any impact, crack or dent.

Pros of Hard Hat Caps:

→ These caps shields workers exposed to certain common threats like cuts, bruises, scratches, bumps etc. during fieldwork.

→ Hard Caps specializes in saving workers from heavy objects falling on their heads, sudden blows, electrical shocks etc.

Cons of Hard Hat Caps:

⊗ These caps provide partial protection to neck and ears only.

⊗ Once gone through any blow, crack or heavy impact these caps are incapable of serving better purpose.

Categories on the Basis of Class

Full Brim Hard Hats and Hard Hat Caps:

Both of these types are generally classified into three categories approved by OSHA (Occupational Safety and Health Administration) and meet the minimum criteria established by the American National Standards (ANSI) and the International Safety Equipment Association (ISEA).

Class G Hard Hats-

-

-

- “G” representing General Hard Hats are designed to reduce subjection to low voltage and offers di-electric protection upto 2,200 volts from phase to ground.

- Common examples include the DAX Fibre Reinforced Hard Hat often worn by iron workers because of iron being a good conductor of electricity and are in dire need of di-electric protection.

- These hats are most commonly sold and designated as ‘Class A” Hard Hats.

-

Class E Hard Hats-

-

-

- “E” representing Electrical Hard Hats are usually worn by utility workers who get frequently exposed to high voltage task on a daily basis.

- These hats provide di-electric protection upto 20,000 volts from phase to ground.

- This amount of voltage protection is limited to the head only, not the whole body.

- These hats are formerly associated with a “Class B” rating.

-

Class C Hard Hats-

-

-

- “C” representing Conductive Hard Hats, do not provide protection against electrical conductors.

- However, these hats include vented options providing protection against impact and compression.

- BRIGGS Vented Hard Hat is a common example of this type.

-

FAQ

What to keep in mind while choosing either of these two?

-

-

- The choice of selecting any one of these two types of hard hats depends on one’s profession and specific safety requirements, on duty.

- While Full Brim Hard Hats offer around protection to your face, nose, ears and neck from natural conditions, Hard Caps give partial protection from your head to neck.

- Both these types can withstand a peek force of 1000 pounds.

-

Do all hard hats (Full Brim and Caps) provide impact protection from all ways?

Hard Hats (Full Brim and Caps) are divided into two types on the basis of protection-

TYPE 1-

-

-

- Designated to protect only the top of the head from a strong impact or a blow, vertical to the top of the head.

- For e.g. MSA V-Guard Hard Hat.

-

TYPE 2-

-

-

- Designated for vertical as well as lateral protection of the head.

- Built with high density thick foam suspension.

- For e.g. MSA Super V Hard Hat.

-

Which is more cost efficient?

-

-

- According to MSA safety.com Full Brim Hard Hats ranges from $8 to $120.

- Hard Caps ranges from $4 to $335 available at MSA safety.com.

- For more information kindly visit amazon.com.

-

How frequently should we replace the hats?

-

-

- It is recommended to replace these hats after every 12 months before reaching its expiry date.

- Although, you are advised to replace them they become soft and weak, without waiting for the expiry date.

-

Wrapping up!

I, therefore, conclude with the view that safety and protection go hand in hand and cannot be compromised.

“Prevention is, and always be better than cure”.

Henceforth, always keep in mind to protect and prepare yourself for any type of hazards which might be coming your way. Always go for proper and good quality safety gears while working because “Work comes first”. Workgearz.com puts your safety on priority before anything else.

See you all soon with something new!

Till then stay safe and healthy!