If you work at the construction site, be it in any field, whether as a worker or an engineer or a supervisor; you need to protect your head from injuries from falling objects or collisions with stationary objects or hit by a sharp object and electric shocks. For this purpose you need a hard hat which is actually made mandatory by the law.

If you work at the construction site, be it in any field, whether as a worker or an engineer or a supervisor; you need to protect your head from injuries from falling objects or collisions with stationary objects or hit by a sharp object and electric shocks. For this purpose you need a hard hat which is actually made mandatory by the law.

But nothing is made to last forever. Your health too gives up at the old age. So, anything including protective equipments can save you from fatalities till a certain point of time; till they are capable of rendering the protective qualities in them.

Hard hats too are no exceptional! They too will cease to give protection after a period of time.

But the question is…WHEN?

Well that is what I am here for today…

To make you understand and aware of the right time to replace your hard hat!

And before we even start the article, I am going to tell you it’s between 3 to 5 years of regular use that the hard hats must be replaced (ssshhhhhh don’t tell anyone!)

Why Do You Need a Hard Hat?

Not only hard hats are made compulsory by law, but they are required for personal safety in work places where you have the probabilities of getting a head injury from falling objects or from hung objects and also sharp objects as well.

So, while at work, you can work safely without worrying about being getting hit by any object because the hard hat would be resisting the impact of the impending load and thus save your head from injuries.

But this is not all that a hard had does! It also does an exceptional job of protecting you from electric shock. Yes, Class E hard hats are meant to offer protection from electric current while you may be working with the electric connections or circuits.

How Much Impact can Hard Hat Take?

When it comes to withstand load, a hard hat can take as much as 8 pound weights falling from a height of 5 feet above. The test for impact on hard hats goes as far as putting a load of 1000 pounds in temperatures ranging from 0 degree F and 120 degrees F.

When you talk about impacts, it’s not always the load but also getting hit by sharp objects. In that case, a hard hat can withstand a 2.2 pound pointed object (mostly steel or iron) falling from a height of 8 feet.

So, just imagine what extent of protection can a hard hat offer you and save you from fatalities.

Are you Using the Right Hard Hat?

Not all hard hats will offer the same level of protection as some are made of cheap materials. So, it’s very important to know whether the hard hat you are buying or using is capable of saving your life!

But the question is how?

We are not aware of the exact composition of our hard hats and frankly speaking we will not know whether its safe or not until any casualties.

But do you want to take that chance?

Obviously no!

Thank God! There is one easy way to find out whether you are using a good hard hat and that is having a label of a standard based on which it was made.

Hard hats should be made following the OSHA and ANSI standards and based on it hard hats are categorized into type 1 and type 2. (What Type of Hard Hats are Not ANSI Approved?)

Type 1 hard hats are meant to withstand load coming from above and Type 2 hard hats are meant for protection from front, side and rear.

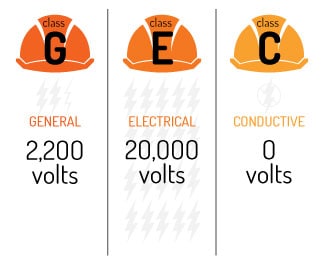

And in terms of electrical shock resistance, hard hats are categorized into 3 Classes: E, C & G.

CLASS C stands for the conductive hard hats which offer no electric resistance.

Class G stands for general which offers protection from 2200 volts for 1 minute.

Class E stands for electrical hard hats which are first tested for impact resistance and then tested at 20,000 volts for 3 minutes.

The OSHA standard for hard hats is 29 CFR 1910.135.

The ANSI standards are:

- ANSI Z89.1 (2009 version) followed in North America

- CSA Z94.1 (2005 version) followed in Canada

So, the hard hats you buy or wear must contain any of the above standard labels on it or may be some other standards as followed in other countries.

Having these standard labels is an assurance that your hard hat had been tested for impact and protection before being manufactured in the market.

When is the Right Time to Replace your Hard Hat?

In simple words, whenever your hard hat would undergo any damage, be ready to discard it at once. This is because once it has withstood an impact; it will become mis-shaped and will no longer fit proper in your head.

Moreover, after withstanding one impact, the material will get damaged and will lose its protective capacities for the future.

But in case you are lucky enough to get through without any impact on your hard hat for over a couple of years, yet I suggest not using the hard hat for more than 3 to 5 years. This is because not only impacts, but also exposure to chemicals and cleanings and environment deteriorate the material of the hard hats over time.

It’s time to take your leave!

Before I go, just want to tell you a secret! You know your hard hat is getting prone to damage everyday without even your knowledge?

Yes, you heard it right! And the damage is being caused by the Ultra Violet Rays of the Sun (UV radiation).

While you wear your hard hat while working under the sun or just leave it at home beside a wide open window or let it dry in the sun after washing; you are all damaging your hard hat. (Learn How to Clean Hard Hats Like a Pro)

Therefore, try to avoid the sun rays for your hard hat as much as possible and they will last you longer.

Hey! That’s all for today!

Have a good day…

Keep safe…

Stay healthy and…

Work safely!