With electricity you can never take a chance because you do not know when and in which form the electrical hazard is going to attack you. So, you need to be always well equipped while handling or working with electricity.

Rubber is one such material and to be precise the best material to save you from electricity. And the most susceptible part that is exposed to the risk of conducting electricity is your hands. Rubber, being a bad conductor of electricity resists the flow of electric current to your body and thus rubber gloves work best in protecting from electrical hazards.

There are various safety clothing available in the form of PPE to save you from the danger of electricity and these clothing are made of materials that are bad conductors of electricity so that the material can resist the flow of electricity from the circuit to your body.

Why should you wear rubber gloves while working with electricity?

As mentioned earlier, rubber is a bad conductor of electricity which means that it can be used as protection from electricity. Rubber acts as a natural insulator and will prevent the current to flow through your skin.

Therefore, wearing gloves while working with electricity is necessary as in case of electric shock from the source of electricity, rubber gloves will restrict the contact of electricity with your skin and the path of electricity to your body will be disconnected or restricted, thus saving you from the electric shock while repairing an electric switch or appliances.

In order to conduct electricity, materials need to have free electrons in them but rubber lacks those free electrons to conduct electricity and therefore is considered safe as protective material against electricity.

Rubber gloves can save you from up to 600 volts of current, though in US, generally up to 120 volts is used in workplaces in normal conditions.

But one thing to be noted is that the rubber that the glove is made of should be 100% rubber and not mixed with any other material, otherwise the job of protection won’t be done right.

What is the difference between rubber gloves and leather protectors?

To be precise, leather protectors are inserted inside the rubber gloves to make a thick layer, though rubber is a better insulator than leather.

While the rubber gloves act as an insulator from the electric current, leather protectors add a heavy layer to the gloves thus, protecting the hands from the cuts and abrasions from the wires and sharp objects.

Is it possible to get an electric shock while still wearing rubber gloves?

It is highly unlikely that you will get a shock while your rubber gloves are put on. But there are certain cases when there can be no fair play even with the rubber gloves put on. Let’s see what those are!

-

-

- If the rubber gloves are not very thick, there is a probability that some amount of current (though a minimal amount) can flow through you body

- If the rubber gloves have holes in them or are damaged by cuts in them, current can enter the body through those holes

- If your hands are wet or are sweaty, chances are there that it might attract current

- Non-specified rubber gloves (those are not marked safe for electrical purpose) may develop some amount of static charge which can then be conducted to your body

-

Therefore, even if you are wearing rubber gloves, make sure they are marked safe for use in electrical purposes because you can never rely on electricity which might cause hazard in any form.

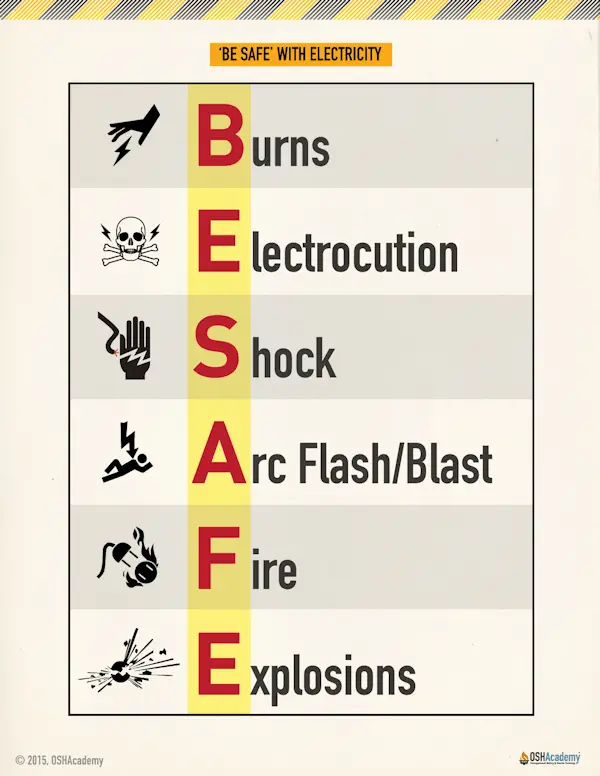

What are the hazards caused from electrical shock?

In general, most of the workplaces use somewhere around 230 to 400 volts supplies of electricity and faults in the circuits and appliances can cause the following hazards:

-

-

- If workers come in contact with the live parts of circuits or appliances, they may receive shocks and burns

- Faults in the appliances and the supplies can cause arc fire

- If any flammable substance is kept near an electrical source, it may explode and cause a massive fire which can even lead to death

-

Factors determining the severity of the effect of electric shock:

Normally, it is the level of voltage of the electric current that the body is exposed to and the resistance of the body to restrict the flow of electricity that determines the severity of damage. Other factors include:

-

-

- The path which the current takes to enter your body

- The amount of time the current flows through the body

- The amount of resistance your body can provide to the current flow

- The level of voltage coming from the source of contact

-

What to do in case of an emergency (when a person has received an electric shock)?

Remember, when a person is stuck to the electric source while in a state of shock, never touch that person. Otherwise current will flow from the person’s body to your body as human body is a good conductor of electricity.

If a worker has come in contact with electric shock, immediately follow the instructions given below:

-

-

- Turn off or try to disconnect the source of electricity from where the body is receiving the current with a wooden stick

- If the source of electricity cannot be turned off, try to separate the person’s body part that is in contact with the current with the help of an object made of wood or fiberglass.

- Turn of the main supply from the MCB and call for an electrician

-

Preventive measures against electric shock:

Both as an employer and as an employee of the workplace, you have the following responsibilities in the prevention of an electrical hazard:

-

-

- Ensure regular checking of electrical installations by a competent person

- Make sure you are use the right cable connectors or couplers in joining the length of cables and never allow taped joints

- You should not overload the socket outlets with adaptors

- The electrical equipments which are fixed, should have a clearly identified switch to cut off the power during emergency

- The portable equipments which are marked as double insulated should have the neutral and the live connected properly to the plug

- Ensure that the fuses are always properly fitted

- Make sure high voltage equipments draws power from an earthed source

- You should always provide one or more residual current device

- Always test a device and the wire before installing them in the workplace

-

What kind of gloves do electricians wear?

An electrician should select gloves with the following features:

Material: First of all, the gloves should be made of rubber and there should be present a leather protector. The next thing to note is that the gloves are made o non-flammable material.

Insulation: The best insulation is provided by rubber that has a leather protection on top of it.

Fitting:

The gloves should fit right on your palms. It should be loose at all.

Also, there are 6 classes of electrician gloves that are outlined by OSHA:

Class 00: usage in voltage up o 500V AC

Class 0: usage in voltage up to 1000V AC

Class 1: usage in voltage up to 7,500V AC

Class 2: usage in voltage up to 17,000V AC

Class 3: usage in voltage up to 26,500V AC

Class 4: usage in voltage up to 36,000V AC

Another classification is based on the ozone resistance of the gloves wherein Type I offers no resistance and Type II offers resistance against ozone.

Why should an electrician wear gloves?

An electrician should wear for the following reasons:

-

-

- Gloves offer barrier against electrocution

- Gloves protect against scratches abrasions and cuts

- It also helps to keep the hands clean while handling burnt wires and appliances

-

It’s time to bid Adieu!

It’s time to wrap our discussion on wearing rubber gloves while working with electricity and I hope that the information provided in this article was useful to you!

Will be back soon with another article. Till then take care and stay safe!

Have a great day ahead!